An industrial visit to Element Materials Technology in Aberdeen to attend the technical presentation of “Sour Service Testing of Carbon Steel Girth Welds” by Phil Dent, Element’s Global Corrosion Specialist, followed by a visit to the new H2S / Sour Service Laboratories.

An introduction was delivered by Ian Farquharson- General Manager of Element Aberdeen and Edinburgh branches, who declared that Element is ranked as the 5th biggest materials testing and certification firms in the world following its recent merger with EXOVA. He also mentioned that Element Aberdeen is a UKAS and ISO/IEC 17025 accredited laboratory which offers one of the most comprehensive ranges of metallurgical materials testing and analysis services in the UK including mechanical testing, fracture toughness testing, engineering critical assessments (ECA), metallurgy and materials characterization, failure investigation, chemical analysis, corrosion testing and welding engineering services to multi-sector clients around the world.

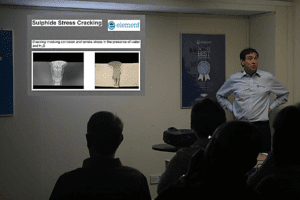

Phil Dent of Element started the technical presentation by a definition of sour service condition followed by description of various types of sour service cracking mechanisms and the environmental factors affecting the susceptibility of materials under sour service regimes. The sour service cracking mechanisms which were presented by Phil included Sulphide Stress Cracking (SSC), Hydrogen Induced Cracking (HIC), Stress Orientated Hydrogen Induced Cracking (SOHIC), and Soft-Zone Cracking (SZC). The various test methods such as Four Points Bend test (NACE TM0316), C-Ring test (NACE TM0177, Method C), Full Ring test (BS 8701), and Uniaxial tensile test (NACE TM0177, Method A) were explained by the presenter.

Phil Dent, Element’s Global Corrosion Specialist explains SSC Phenomenon

Phil Dent, Element’s Global Corrosion Specialist explains SSC Phenomenon

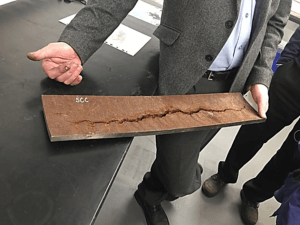

The corrosion testing laboratory visit was accomplished under supervision of Paul Roberts – Corrosion and Chemistry Manager after a brief introduction of the safety points. The corrosion testing services cover a full range of environmental testing simulations, including pipeline corrosion testing for sour and non-sour applications, hydrogen testing, pitting, full ring tests, as well as SCC tests.

Element Laboratories in Aberdeen, specialise in materials qualification for sour service applications and offer standard HIC, SSC tests and also more specialised Full Ring and SOHIC tests and follow such international testing standards and protocols as ASTM, IP MIL and NACE. The summarised information about the facilities and test procedures for H2S sour service axial tensile test, high temperature / high pressure, electrochemical tests and strain gauging was delivered by Paul.

Element Laboratory Example of Serious SCC Type Cracking

Element Laboratory Example of Serious SCC Type Cracking

The questions raised by attendees during the technical presentation and laboratory visits were well responded to by the Hosts. This event attracted a high interest within the professionals and executives of major oil and gas operators, engineering consultancies, and service companies in Aberdeen, to attend and take the benefits by visiting one of the major testing and materials qualifications bodies here in United Kingdom. Overall, it proved to be an excellent event in every respect.

For Copy of the newsletter please click link below: