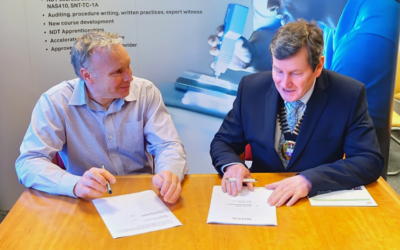

The presentation given by Dustin was excellent, raising a significant discussion amongst those attending. Dustin’s idea was to raise awareness of new predictive modelling techniques for coating life and performance. A new generation of high temperature coatings, such as high glass transition temperature Fusion Bonded Epoxy (with Tg 205°C), are being developed as a lower cost alternative to expensive alloy steels. However, the highly-functional epoxy resin and ingredients in these new coatings can make interpretation of testing results difficult for coating specifiers. Dustin Traylor, MSE and Dr. Stephen Drew of Axalta Coating Systems explore the benefits of using Electrochemical Impedance Spectroscopy (EIS) after atmospheric testing to assess a coating’s life expectancy. This technique has now been adopted by Aramco and Chevron and is gaining credibility as a useful tool in the pipeline market.

The conclusion was that EIS did have a part to play in conjunction with accelerated weathering; Autoclave and Atlas Cell to assist with the determination of expected coating life.

To verify the laboratory work to date, the Axalta team needs field data on aged coatings to establish if this is an appropriate standard for testing of coatings

For copy of the Newsletter please click below: