Institute of Corrosion Awards

Detailed below are the awards presented by the Institute of Corrosion. Information on how to nominate someone for these awards can be found below under ‘Award Criteria’; for more information please contact us

U R Evans Award

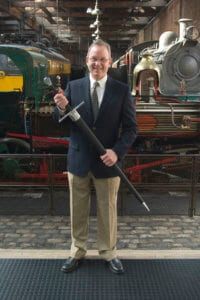

This is the premier scientific award of the Institute of Corrosion. It was first awarded in 1976 and is made for outstanding international achievements in pure or applied corrosion science. The recipient is selected by a Corrosion Science Division panel and presented with an engraved sword at the annual Corrosion Science Symposium. The recipient also receives an Honorary Life Fellowship of the Institute.

Background of U R Evans Award

This Award had its origins in discussions in the Council of one of the founding partners of this Institution, CAPA, during 1972 and 1973. It was agreed by that Council, in winding up CAPA affairs, that this responsibility could be discharged in no better way than to establish an Award, to be presented by the new body at the annual Corrosion Science Symposium. This event, which predates both the founding bodies of the Institute, is in many ways unique in the corrosion calendar of the UK. In particular, the event is one which seeks to encourage the participation of the younger members of the corrosion community who would appreciate the visit of, and address by, a corrosion scientist of international repute.

The form of the Award symbolises the fight in which we are all engaged. Following the merger, the committee of the Corrosion Science Division made its proposals to the National Council of the Institution of Corrosion Science and Technology and these were agreed to be a suitable use for the trust fund. U.R. Evans was approached and gave the committee the honour of allowing the Award to carry his name. In giving his consent, U.R. Evans highlighted two key points. First, that he regarded the naming of the Award to be a pleasing recognition of the many younger women/men who had worked with him at Cambridge and second, that he felt great sympathy with a policy that over the years would encourage foreign scientists to come to this country and make contacts beneficial to corrosion science in particular – to science in general – and do something to promote peace in the world.

U.R. Evans was born in Wimbledon and educated at Marlborough College, 1902-1907, and King’s College, Cambridge, 1907-1911, where he read for the Natural Sciences Tripos, specialising in chemistry for Part II. He then began research on electrochemistry at Wiesbaden and London, which was cut short by the First World War. He served in the army from August 1914 until 1919.

At the end of the war he returned to Cambridge where he spent the rest of his life, researching and writing prolifically on corrosion and oxidation of metals. Ulick Evans is described in the Biographical Memoirs of Fellows of the Royal Society as the “Father of the modern science of corrosion and protection of metals”. His major contribution to the subject involved placing on a firm foundation the electrochemical nature of corrosion.

His first paper in this area was published in 1923, which was followed in 1924 by his book “Corrosion of Metals”, the first textbook devoted to the subject. He continued to publish research papers for the next 50 years, as well as updating his classic text.

List of Past Recipients

Dr Peter Andresen (General Electric) received the 2014 U R Evans Award at the Museum of Science and Industry, Manchester

2023 Prof N Birbilis

2022 Prof A Davenport

2021 Prof M Ryan

2020 Prof R Cottis

2019 Prof T Shoji

2018 Prof A Neville

2017 Dr H Isaacs

2016 Prof R Gangloff

2015 Prof D Williams

2014 Dr P Andresen

2013 Prof J Scully

2012 Prof M Schütze

2011 Prof G Frankel

2010 Prof P Marcus

2009 Prof C Leygraf

2008 Prof D Young

2007 Prof D Scantlebury

2006 Prof G T Burstein

2005 Prof M Stratmann

2004 Dr A Turnbull

2003 Prof R Newman

2002 Prof D D Macdonald

2001 Prof F H Stott

2000 Prof G E Thompson

1999 Prof J R Galvele

1998 Prof C Page

1997 Prof H Grabke

1996 Prof S Mrowec

1995 Prof P Hancock

1994 Dr M J Graham

1993 Prof J Stringer

1992 Prof R A Rapp

1991 Prof J Kruger

1990 Prof H Spähn

1989 Dr J C Scully

1988 Prof R Parkins

1987 Prof P Kofstad

1986 Dr J E O Mayne

1985 Prof N Sato

1984 Mr F L Laque

1983 Prof G C Wood

1982 Prof H J Engels

1981 Mr J B Cotton

1980 Prof H H Uhlig

1979 Dr M Pourbaix

1978 Dr L L Shreir

1977 Prof P Lacombe

1976 Dr T P Hoar

Award Criteria

- International reputation and service to the corrosion science community

- Contribution to dissemination – publications, professional bodies, patents and IPR, conferences and events

- Contribution to industry – especially of an interdisciplinary nature

- Contribution to corrosion science and technology training

- Distinctiveness, originality and creativity of research – impact on corrosion discipline

- Seminal contribution to corrosion science and practice

- Continuing potential contribution to corrosion research

Nominations may be submitted at any time to the Chair of the Corrosion Science Division, Dr Julian Wharton (j.a.wharton@soton.ac.uk)

Presentation of Award

The U R Evans Award is presented at the annual Corrosion Science Symposium. The recipient is asked to give a plenary talk of their choosing and to prepare a brief written article on their work for publication in Corrosion Management (subject to editing by the Corrosion Management editor).

Paul McIntyre Award

The Paul McIntyre Award is the premier engineering award of the Institute of Corrosion. It was first awarded in 2017 and is presented to a senior corrosion engineer, who, as well as being a leading practitioner in his field, has advanced European collaboration and international standards development.

Background of Paul McIntyre Award

Dr Paul McIntyre graduated from the University of Newcastle upon Tyne with a 1st class honours degree. He spent his early career in the steel industry. In 1978 he moved south and joined the Central Electricity Research Laboratories in Leatherhead as group leader of EAC studying stress corrosion, localised corrosion and corrosion fatigue in conventional and nuclear power plants. Later he was involved in asset management and remaining life assessment of components, including development of remedial methodologies such as RAM (reliability, availability and maintainability) and RCM (reliability centred maintenance).

From 1996 until 2006, he was Editor of the British Corrosion Journal (which became Corrosion Engineering Science & Technology). For six years from about 2004 until 2010 he worked as consultant in the Electrochemistry & Corrosion group at the National Physical Laboratory. His scientific insight and depth of engineering experience was critical to successful analysis of a wide range of failure investigations, including fracture of wind turbine bolts, corrosion pitting in a desalination plant as well as providing informed corrosion control guidance to industry.

Paul wrote almost 60 published papers and over 200 internal reports. In addition to his career in industry, Paul had almost 30 years of participation in corrosion standardisation within BSI and ISO committees. These included being chair of ISO/NFE 8 Corrosion of metals and alloys, and UK representative on the equivalent ISO committee TC 156 and within that being secretary of WG 2 Stress Corrosion Cracking and member of WG 7 Accelerated Corrosion Tests.

Paul made an immense contribution as Scientific Secretary of the European Federation of Corrosion. He was also on the Council of the Institute of Corrosion from the early 2000s, specialising in standards work and pan-European activities. In 2003 Paul was awarded the T B Marsden prize of IOM3 for his considerable achievements in promoting standards, education and publishing in corrosion and materials. The chair of ISO TC 156 stated in the award citation “Paul has provided more input into the development of ISO standards in the corrosion field than any other individual”. Paul was invariably polite and accommodating to everybody. But he had a core of steel and a dry sense of humour. In 2010 he was diagnosed with secondary liver cancer and very sadly passed away in 2012.

List of Past Recipients

Award Criteria

The Paul McIntyre Award is presented to a senior corrosion engineer, who, as well as being a leading practitioner in his field, has advanced European collaboration and international standards development (in keeping with Paul’s areas of interest). The criteria for the recipient of this award are as follows:

• They have established an international reputation in the field of corrosion engineering

• They have demonstrably advanced European collaboration and international standards development in the field of corrosion engineering

• They must be living and working in the European corrosion community

• They must be a member of a corrosion-related body in the European area (e.g. ICorr, NACE UK, IOM3 or another European corrosion society)

• They must not be a current member of the Council of the Institute of Corrosion

Nominations for this award may be submitted at any time to the Chair of the Corrosion Engineering Division Chair, Dr Danny Burkle (D.Burkle@lbbcbaskerville.co.uk)

Presentation of Award

The Paul McIntyre Award is presented at the annual Corrosion Engineering Symposium & Working Day. The recipient is asked to give a plenary talk of their choosing and to prepare a brief written article on their work for publication in Corrosion Management (subject to editing by the Corrosion Management editor).

H G Cole Award

This presentation is in the form of a plaque and is for exceptional services to the development of the Institute.

Background of H G Cole Award

Henry George Cole was the Chief Materials Engineer at the UK Ministry of Defence. He was based in London and Farnborough, but he was a hugely respected co-ordinator and sponsor of research, an elegant and influential ‘Whitehall Mandarin’, and a man of spectacular vision and determination.

Henry George Cole was the Chief Materials Engineer at the UK Ministry of Defence. He was based in London and Farnborough, but he was a hugely respected co-ordinator and sponsor of research, an elegant and influential ‘Whitehall Mandarin’, and a man of spectacular vision and determination.

On first meeting, it was easy to assume that Henry Cole was a tall, austere, rather forbidding and remote character who stood aloof from the general mêlée in the room, surveying the scene at arm’s length and from behind the haze of his cigarette. This demeanour camouflaged an ace of the Scientific Civil Service. He was the consummate civil servant, fluently at home anywhere and in any company, and with a negotiation style David Gearey characterised as being akin to ‘the sidestep of a wing-three-quarter’.

Based initially at the RAE in Farnborough and subsequently in London, he was directly responsible for supporting the co-deposition work undertaken by Peter Neufeld and John Foster at South Bank Polytechnic (now University of London) in conjunction with British Aerospace, the results of which were patented and are still in use on applications such as engine cylinder liners. He sponsored work on embrittlement and its avoidance on cadmium plated aerospace components. He was behind the fundamental research on electrochemical machining that later found application in the production of gas turbine blades, and he also supported Dr. Michael Clarke’s research on gold electroplating at City of London Polytechnic. These are just a few examples of the developments over which he presided.

He was Secretary to the Hoar Committee – a ground-breaking development for the recognition of corrosion cost in the early 1970’s which was the mainspring for corrosion interest in UK Government circles for the next twenty years.

Henry Cole also was hugely committed to the Institute of Corrosion. He became the part-time Administrative Officer for the Institute when it shared accommodation with the SCI at Belgrave Square. He oversaw the Institute’s move to the IMF offices in Birmingham and he was one of the guiding lights of the Institute until his untimely death on 14th May 1987. Professor Stuart Leach of Nottingham University, himself a noted leader and innovator in the field, dubbed him “The Impresario of Corrosion Research” for his work on behalf of the corrosion control industry.

At its introduction in 1997 by the Institute of Corrosion, the primary objective of the H G Cole Award, however, was not to add to the list of Awards that recognise innovative contributions in scientific development, though aspects of those activities might be contributory. The purpose of the award was specifically to recognise exceptional service in support of the Institute of Corrosion itself.

Thus, it was envisaged that the Award, which originally consisted of a certificate and poignard (in essence, a small dagger), should be awarded by the Council of the Institute to nominated candidates on an occasional basis in recognition of ‘Exceptional Service on behalf of the Institute of Corrosion’.

The inaugural award was presented to Charles Booker in 1997 by Gwen Cole (wife of the late Henry Cole) in recognition of his many years of service as Honorary Secretary of the Institute.

The modern form of the award is a plaque whose design captures the essence of the original poignard.

List of Past Recipients

2023 Trevor Osborne

2021 Bill Cox

2001 Roger Hudson

2001 Peter Morgan

2000 Fred Palmer

1997 Charles Booker

Award Criteria

- The Nominee should have a long-term and consistent history of exceptional commitment in support of the Institute of Corrosion

- The Nominee will have contributed successfully in assisting the Institute in its quest to attain significant improvement in enhancing the reputation and standing of the Institute itself

- The Nominee will have led, or will have contributed significantly to initiatives that have enhanced the ability of the Institute to improve corrosion prevention and control, on a national and/or international basis, by sponsorship of innovation and/or the support of ICorr training and certification

- The Nominee will have been directly instrumental in improving the fiscal position of the Institute and/or its offices and/or accommodation

Nominations for the award are accepted at any time from the President of the Institute (on behalf of Council) by the Chair of the ICorr Awards Committee.

Presentation of Award

The H G Cole Award is presented at an appropriate event, such as the London Branch Christmas Luncheon or the ICorr AGM.

T P Hoar Award

Dr Hoar was the first recipient of the U R Evans Award and the prize in his memory is awarded by a sub-committee of the Corrosion Science Division for the best paper published each year in Corrosion Science.

Background of TP Hoar Award

Dr Thomas Percy Hoar, formerly Reader in Chemical Metallurgy in the University of Cambridge, died in May 1978. His achievements in corrosion science and engineering were enormous; he published well over a hundred papers on topics as diverse as passivity, inhibition and stress corrosion; he received the Whitney Award from the National Association of Corrosion Engineers, the Hothersall Medal of the Institute of Metal Finishing, the Palladium Medal of the Electrochemical Society and the U R Evans Award of the then Institution of Corrosion Science and Technology; he was the founder Chairman of the Corrosion and Protection Association and President of the Institution of Corrosion Technology; he was Editor-in-Chief of Electrochimica Acta and on the Editorial Board of Corrosion Science; he was the author of the Hoar Report on Corrosion for the UK Department of Trade and Industry.

After an unusually full and rich life ‘Sam’ Hoar was remembered fondly and with gratitude by generations of students and fellow scientists all over the world. To commemorate his outstanding contributions to pure and applied corrosion science and his long associations with the Institution, its predecessors, and the journal Corrosion Science, and also to recognize publication in Corrosion Science of seminal or otherwise outstanding research in pure or applied corrosion science, the Institution of Corrosion Science and Technology T P Hoar Award was established. The T P Hoar Award, which originally consisted of an engraved certificate and a monetary award of £200, is awarded annually by the Council of the Institute, on the recommendation of the Corrosion Science Division Committee, to the author or authors (irrespective of number, age, nationality or membership of the Institute) of a paper published in Corrosion Science in the previous calendar year of outstanding scientific and/or technological merit.

The T P Hoar award, which is in part supported by Elsevier, the publishers of Corrosion Science, was awarded for the first time in 1981, to a paper published in Volume 20 (1980) of Corrosion Science. The first recipients of the Prize were announced at the 22nd Corrosion Science Symposium held in Newcastle-upon-Tyne on 15-18 December 1981.

Thomas Percy Hoar was born in Rochester, England on 16 November 1907. His early education was obtained in that city at Sir Joseph Williamson’s Mathematical School. He later attended Sidney Sussex College, Cambridge, and was awarded his Ph.D. degree from the University of Cambridge in 1933, for studies of the corrosion of iron and of the oxygen electrode. In 1958, he received the Doctor of Science degree.

His paper, co-authored with U R Evans in 1932, on the velocity of corrosion was among the first to correlate corrosion rate quantitatively with measured electrochemical reaction rates. He performed important studies for the International Tin Research and Development Council. In the early 1940s, his studies on inhibiting corrosion, mainly by the use of sodium nitrite, contributed important knowledge. In 1946, Dr Hoar was appointed lecturer in the Department of Metallurgy at the University of Cambridge, and Reader in Chemical Metallurgy in 1966. He was editor-in-chief of Electrochimica Acta from the time of its inception in 1959. He was instrumental in the founding and was second President of the International Committee for Electrochemical Thermodynamics and Kinetics.

A fitting T P Hoar quote: “Now what I wanted to say was, many of these things are to be found in the literature, and not only the recent literature, either. I think we all ought to go home and do considerably more reading, and far less experimental work. People will not read the literature. Most of it is there already.“

List of Past Recipients

2022 A. Kosari, H. Zandbergen, F. Tichelaar, P. Visser, H. Terryn, J.M.C. Mol, Challenges to electrochemical evaluation of nanometric sandwiched thin specimens using liquid cells designed for application in liquid-phase TEM corrosion studies, Corrosion Science, Vol. 192, 109864 (2021)

2021 A. Kosari, H. Zandbergen, F. Tichelaar, P. Visser, P. Taheri, H. Terryn, J.M.C. Mol, In-situ nanoscopic observations of dealloying-driven local corrosion from surface initiation to in-depth propagation, Corrosion Science, Vol. 177, 108912 (2020)

2020 R.D. Hanbury, G.S. Was, Oxide growth and dissolution on 316L stainless steel during irradiation in high temperature water, Corrosion Science, Vol. 157, pp. 305-311 (2019)

2019 R.J. Wilbraham, C. Boxall, R.J. Taylor, Photocatalytically driven dissolution of macroscopic nickel surfaces, Corrosion Science, Vol. 131, pp. 137-146 (2018)

2018 Z. Peng, M. Rohwerder, P-P. Choi, B Gault, T. Meiners, M. Friedrichs, H. Kreilkamp, F. Klocke, D. Raabe, Atomic diffusion induced degradation in bimetallic layer coated cemented tungsten carbide, Corrosion Science, Vol. 120, pp. 1-13 (2017)

2017 W. Mai, S. Soghrati, R.G. Buchheit, A phase field model for simulating the pitting corrosion, Corrosion Science, Vol. 110, pp. 157-166 (2016)

2016 M. Auinger, V.G. Praig, B. Linder, H. Danninger, Grain boundary oxidation in iron-based alloys, investigated by 18O enriched water vapour – The effect of mixed oxides in binary and ternary Fe-{Al, Cr, Mn, Si} systems, Corrosion Science Vol 96, pp 133-143 (2015)

2015 X. Liu, H. Spikes, J.S.S. Wong, In situ pH responsive fluorescent probing of localized iron corrosion, Corrosion Science, Vol 87, pp. 118-126 (2014)

2014 G.F. Frankel, A. Samaniego, N. Birbilis, Evolution of hydrogen at dissolving magnesium surfaces, Corrosion Science, Vol. 70, pp. 104-111 (2013)

2013 M. Breimesser, S. Ritter, H.-P. Seifert, S. Virtanen, T. Suter, Application of the electrochemical microcapillary technique to study intergranular stress corrosion cracking of austenitic stainless steel on the micrometre scale, Corrosion Science, Vol. 55, pp. 126-132 (2012)

2012 D.A. Horner, B.J. Connolly, S. Zhou, L. Crocker, A. Turnbull, Novel images of the evolution of stress corrosion cracks from corrosion pits, Corrosion Science, Vol. 53, pp. 3466-3485 (2011)

2011 B. Ingham, M. Ko, G. Kear, P. Kappen, N. Laycock, J.A. Kimpton, D.E. Williams, In situ synchrotron X-ray diffraction study of surface scale formation during CO2 corrosion of carbon steel at temperatures up to 90 °C, Corrosion Science, Vol. 52, pp. 3052-3061 (2010)

2010 M.M. Hall Jr., Film rupture model for aqueous stress corrosion cracking under constant and variable stress intensity factor, Corrosion Science, Vol. 51, pp. 225–233 (2009)

2009 E. Remita, B. Tribollet, E. Sutter, V. Vivier, F. Ropital, J. Kittel, Hydrogen evolution in aqueous solutions containing dissolved CO2: Quantitative contribution of the buffering effect, Corrosion Science, Vol. 50, pp. 1433-1440 (2008)

2008 X. Liu, G.S. Frankel, B. Zoofan, S. Rokhlin, In-situ observation of intergranular stress corrosion cracking in AA2024-T3 under constant load conditions, Corrosion Science, Vol. 49, pp. 139-148 (2007)

2007 M.H. Moayed, R.C. Newman, Evolution of current transients and morphology of metastable and stable pitting on stainless steel near the critical pitting temperature, Corrosion Science, Vol. 48, pp. 1004-1018 (2006)

2006 Y. Huang, Y. Zhu, Hydrogen ion reduction in the process of iron rusting, Corrosion Science, Vol. 47, pp. 1545-1554 (2005)

2005 E. Tada, K. Noda, S. Kumai, T. Tsuru, Monitoring of corrosion fatigue cracking using harmonic analysis of current responses induced by cyclic stressing, Corrosion Science, Vol. 46, pp. 1549-1563 (2004)

2004 R. Jeffrey, R.E. Melchers, Bacteriological influence in the development of iron sulphide species in marine immersion environments, Corrosion Science, Vol. 45, pp. 693-714 (2003)

2003 P. Ernst, R.C. Newman, Pit growth studies in stainless steel foils, Corrosion Science, Vol. 44, pp. 927-954 (2002)

2002 S.B. Hong, N. Eliaz, E.M. Sachs, S.M. Allen, R.M. Latanision, Corrosion behaviour of advanced titanium-based alloys made by three dimensional printing for biomedical applications, Corrosion Science, Vol. 43 pp. 1781-1791 (2001)

2001 D.G. Kolman, J.R. Scully, An assessment of the crack tip potential of b-titanium alloys during hydrogen environmentally assisted crack propagation based on crack tip and passive surface electrochemical measurements, Corrosion Science, Vol. 42, pp. 1863-1879 (2000)

2000 A. Leng, M. Streckel, M. Stratmann, The delamination of polymeric coatings from steel: Part 1 Calibration of Kelvin probe and basic delamination mechanisms, Corrosion Science, Vol. 41, pp. 547–578 (1999)

1999 L. Robbiola, J.-M. Blengino, C. Fiaud, Morphology and Mechanisms of Formation of Natural Patinas on Archaeological Cu-Sn Alloys, Corrosion Science, Vol. 40, pp. 2083-2111 (1998)

1998 N.J. Laycock, R.C. Newman, Localised dissolution kinetics, salt films and pitting potentials, Corrosion Science, Vol. 39, pp. 1771-1790 (1997)

1997 M.A. Páez, T.M. Foong, C.T. Ni, G.E. Thompson, K. Shimizu, H. Habazaki, P. Skeldon, G.C. Wood, Barrier-type anodic film formation on an Al-3.5 wt% Cu alloy, Corrosion Science, Vol. 38, pp. 59-72 (1996)

Presentation of Award

The TP Hoar Award recipient is notified via a letter, with an enclosed certificate and cheque for £400.

Lionel Shreir Award

Dr Shreir was also a recipient of the U R Evans Award and this award is made for the best student presentation at the annual Corrosion Science Symposium.

Background of Lionel Shreir Award

Lionel Louis Shreir (12 November 1914 – 5 November 1992). His industrial career spanned a period of 19 years, from 1929 to 1948, during which time he was employed by the Mond Nickel Company, Baker Platinum Ltd and Plessy Ltd. At the same time he continued his higher education on a part time basis at the Chelsea and Battersea Polytechnics and Sir John Cass College in London, and obtained his PhD on electrodeposition of copper. In 1948 he joined the staff of Battersea Polytechnic (subsequently renamed the University of Surrey). In 1962, he became the Head of Metallurgy and Materials at Sir John Cass College where he engaged in teaching and research (a post he enjoyed by greatly expanding the department, its research and general reputation until he retired in 1979), and finally Professor Emeritus of the City of London Polytechnic. He edited and contributed to the ‘Corrosion’ textbook/encyclopaedia (two volumes in 1963). He was also a Fellow of the Royal Institute of Chemists and of the Institution of Metallurgists.

The standards he set were of the highest order. Indeed, his fellow corrosion engineers and scientists recalled the immense pains he took at that time to encourage in the kindest possible way younger authors in their endeavours to write papers. Within the UK he was prominent in all aspects of corrosion education. He was widely sought after for advice on all aspects of industrial problems. He regarded such activities as an essential function for anyone attempting to teach corrosion courses. Among many things, he advised on the construction of the Thames Barrier at Greenwich, North Sea Oil platforms and on corrosion hazards of ships carrying aggressive cargos. His interest in industrial problems arose partly, at least, from his early working life in several industrial laboratories on metal finishing and extraction. His research covered many areas, particularly hydrogen effects on steels. In 1982 he was awarded the OBE (Order of the British Empire) in the Queen’s Birthday Honours ‘for services to corrosion science’. He was the third recipient of the U R Evans Award in 1978. This particular honour gave him great pleasure since he always attributed his start in the corrosion field to the encouragement given to him by Dr Evans during a visit to Cambridge in 1950. Amid all these achievements and distinctions Lionel Shreir remained an extremely modest man, very interested in people, enthusiastic in discussing all aspects of corrosion, and very caring for his past students. He was a very kind man, highly regarded and liked by all who encountered him.

The Shreir prize is presented annually for the best student presentation at the Corrosion Science Symposium.

List of Past Recipients

2022 Alyshia Keogh (University of Manchester)

2021 Lawrence Coghlan (University of Loughborough) and Charlie Wand (University of Manchester)

2020 Christos Kousis (University of Swansea)

2019 Amelia Langley (University of Bath)

2018 Michael Dowhyj (University of Manchester)

2017 Joshua Owen (University of Leeds)

2016 Kiran Kousar (University of Manchester)

2015 Christopher Evans (University of Manchester)

2014 Angus Cook (University of Birmingham)

2013 Andrew du Plessis (University of Birmingham)

2012 Rosie Grayburn (University of Warwick)

2011 Stefano Neodo (University of Southampton)

2010 Huichao Bi (University of Oxford)

2008 Andrew Bennett (University of Swansea)

2007 Anissa Amimer (University of Manchester)

2006 Cristiano Padovani (University of Birmingham)

2005 Sukanta Ghosh (University of Birmingham)

Award Criteria

- Distinctiveness, originality and creativity of research – impact on corrosion discipline

- Knowledge of corrosion science and practice

- Clarity of presentation and rapport with the Corrosion Science Symposium audience

- Clarity when answering questions

No nomination is required – all student presenters at the annual Corrosion Science Symposium are automatically eligible for this award.

Presentation of Award

The Lionel Shreir Award recipient is notified via a letter with an enclosed certificate and cheque for £125.

Galloway Award

This award was created in 1998 in memory of Jack Galloway, a founder member of the British Association of Corrosion Engineers (BACE) from which the Institute of Corrosion derived, to encourage contributions from students working in any area of corrosion science and corrosion engineering.

Background of Galloway Award

Jack Galloway, a founder Member of the British Association of Corrosion Engineers (BACE) and Former Chairman of BACE Council. The original Galloway medal was for young corrosion scientists, under the age of 25, and was based on an essay submission, or a work project report. The Galloway medal was presented at the Corrosion Science Division Annual Symposium and the first award was made in September 1976 at the 17th Corrosion Science Symposium.

The Galloway Award was reinstated in 1998 in memory of Jack Galloway to encourage contributions from students working in any area of corrosion science and corrosion engineering. Students were invited to submit a short technical article discussing their work for consideration for the award. The winning article is published in Corrosion Management, and the prize consists of a certificate and a cheque for £300.

In 2018, the Galloway Award was again revitalised and now only requires students to send a copy of a submitted or published paper from the previous 12 months, rather than a separate technical report. The student should be the primary author of the work and preferably first author. Supervisors may nominate students. These changes keep to the spirit of the award as this was always for dissemination of high quality research, but it makes submission much more accessible. The submission deadline is the first week of September to align with the Corrosion Science Symposium.

List of Past Recipients

2022 Qingyang Liu (University of Leeds)

2021 Stacy Moore (University of Bristol)

2019 Liberato Volpe (University of Manchester)

2018 Mohamed Koronfel (Imperial College)

2017 Stacy Moore (University of Bristol)

2016 Antonios Banos (University of Bristol)

2012 Michael Lowden (University of Birmingham)

Award Criteria

- Distinctiveness, originality and creativity of research – impact on corrosion discipline

- Contribution to corrosion science and practice

- Clarity of presentation

Submissions may be made at any time to the Chair of the Corrosion Science Division, Dr Julian Wharton (j.a.wharton@soton.ac.uk)

Presentation of Award

The Galloway Award recipient is notified via a letter with an enclosed certificate and cheque for £300.