Industry News

Project Background

Holyhead station, a prominent railway station situated in Wales. Strategically located near a harbour and high street, it serves as a key transport hub, seamlessly connecting the region’s rail and maritime networks. Situated on the harbour, the Grade II listed train station has endured persistent exposure to salty sea air, high humidity, heat from the trains and diesel fumes. This relentless environmental assault has resulted in significant corrosion of the structural steel canopies, causing progressive deterioration of the exposed steel.

The Challenge

Network rail’s current coatings manufacturer could not guarantee their product’s effectiveness due to the harsh location. They needed to find an enhanced paint system that outperforms the currently specified paint system to: Maintain structural integrity Preserve the station’s historical features Reduce maintenance and repair costs.

Solution

The solution implemented was Hexigone’s “smart” corrosion inhibitor, Intelli-ion® AX1, chosen for its superior corrosion protection in harsh environments. Achieving C5-level corrosion resistance, AX1 effectively combats corrosion in highly aggressive environments, such as coastal areas, while delivering longer-lasting corrosion protection. Intelli-ion® AX1 has also endured 1440 hours in salt spray testing (ASTM B117), and offerred enhanced adhesion and colour retention in both laboratory and live testing.

Methodology

To compare performance, two protection systems were applied simultaneously:

• 50% of the train station was painted with astandard system.

•

The remaining 50% was painted with a system enhanced

with Intelli-ion®

Laboratory Test Results

Panels with both standard paint and paint enhanced with

Intelli-ion® AX1, were tested side by side. The addition of AX1 improved corrosion resistance, significantly increased adhesion levels and the bonding of the aluminium primer to the metal surface. 1000 Hours Salt Spray ASTM B117.

Real-World Results

The addition of intelli-ion® AX1 significantly enhanced the 50% repainting process of the mile-long station’s surface, comprised of tool-prepared Victorian cast iron. Contractors observed the following improved application properties; “the paint applied more easily, spread more evenly, and provided more coverage.” By enhancing surface tolerance, AX1 improved adhesion by 163.16%, resulting in a 33% increase in performance. This improvement led to reduced maintenance requirements, delivering a highly efficient, cost-effective solution with enhanced long-term asset protection.

3 Years After Application

Intelli-ion® AX1 demonstrated superior performance compared

to the standard system – designed to provide 15 years of

corrosion protection.

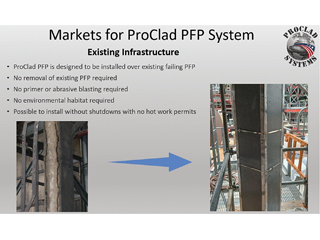

Industry News

ProClad Systems has been working recently in partnership with Jotun paints for the last two years to develop a new pre-cast PFP system that is a composite of ProClad UV-cured GRP + Jotachar JF750 XT intumescent epoxy. The company has recently released the system to the market and is receiving excellent feedback. The greatest interest for the product so far is for the encapsulation of failing cementitious PFP on structural steel, something which is endemic in aged European and North American refineries.

Contact:

Further information, please contact:

David Chalk, Technical Director

UK Mobile: 07484 784 150

Email: david@procladsystems.com

Web: www.procladsystems.com

Photo: Repair of Failed PFP Using ProClad Composite PFP.

Industry News

Esso Australia Resources Pty Ltd (‘Esso Australia’, a subsidiary of ExxonMobil Australia Pty Ltd) has announced a nearly $200 million dollar investment in the Kipper 1B Project which will bring online much-needed additional gas supplies from the Gippsland Basin. Co-venturers for this project are MEPAU A Pty Ltd (‘Mitsui’), and Woodside Energy (Bass Strait) Pty Ltd (‘Woodside’).

“Esso Australia continues to invest in multiple projects that ensure our Gippsland operations sustain gas production well into the 2030s,” says ExxonMobil Australia Chair Simon Younger.

Drilling into the Kipper field is set to begin later this year, with upgrades to the West Tuna platform happening simultaneously.

Source: https://corporate.exxonmobil.com

Industry News

Worley have been awarded a four-year framework agreement for Owner’s Engineering (OE) Services by the Finnish Gas Transmission System Operator, Gasgrid Finland Oy.

The project will extend beyond Finland to cover infrastructure ranging across the Baltic Sea area and Sweden.

Worley will support and advise Gasgrid until 2028 with possible extension to 2032, to ensure the engineering and construction of the onshore pipeline projects are planned and implemented in line with the highest standards and quality. Worley OE services will be provided primarily through Worley offices in The Netherlands and Finland

with support from the Global Integrated Delivery (GID)

team in India.

“Gasgrid’s strategy is to advance the hydrogen economy and renewable energy related investments in Finland,” says Esa Hallivuori, Senior Vice President of Infrastructure Projects at Gasgrid. “With the cooperation of Worley, Gasgrid envisions a long-term partnership to enable strategic project development and infrastructure investments,” added Hallivuori.

Source: https://www.worley.com/

Industry News

Saipem and Subsea7 recently announce that they have reached a memorandum of understanding for a possible merger of the two companies.

Highlights

-

The combination of Saipem and Subsea7 (the “Combined Company”) will be renamed Saipem7, and will have a combined backlog of €43 billion, Revenue of approx.

€20 billion and EBITDA in excess of €2 billion

-

A global organisation of over 45,000 people, including more than 9,000 engineers and project managers

-

Saipem and Subsea7 shareholders will own 50% each

of the share capital of the Combined Company

-

Completion anticipated to occur in the second half

of 2026

Source: https://www.saipem.com/

Contacts

Saipem

Rossella Carrara

Director External Communication and Public Affairs

media.relations@saipem.com

Subsea7

Julie Taylor

Head of Group Communications

communications@subsea7.com

Industry News

Paris, February 18, 2025 – In line with its 2030 ambition to decarbonise the hydrogen used in its European refineries, TotalEnergies has signed agreements with Air Liquide to develop two projects in the Netherlands, for the production and delivery of some 45,000 tons a year of green hydrogen produced using renewable power, generated mostly by the Oranje Wind offshore wind farm, developed by TotalEnergies (50%) and RWE (50%). These projects will cut CO2 emissions from TotalEnergies’ refineries in Belgium and the Netherlands by up to 450,000 tons a year and contribute to the European renewable energy targets in transport.

Green Hydrogen Production by TotalEnergies and Air Liquide

The two companies have signed an agreement to set up a joint venture, equally held by TotalEnergies (50%) and Air Liquide (50%), which will build and operate a 250 MW electrolyser near the Zeeland refinery. This project will enable the production of up to 30,000 tons of green hydrogen a year. This project represents a global investment of around €600 million for both partners and has made requests for support under European and national subsidy programmes.

Contacts

TotalEnergies Contacts Media Relations: +33 (0)1 47 44 46 99 l presse@totalenergies.com l @TotalEnergiesPR Relations Investisseurs : +33 (0)1 47 44 46 46 l ir@totalenergies.com