The question in this issue features solvent free epoxy coatings. Readers are reminded to send in their technical questions for possible inclusion in this column in future.

Question:

I wish to use a solvent free epoxy coating to lower the environmental impact of my maintenance painting project, however when I look at the products available there appears to be a wide range of volatile organic compound (VOC) content in such coatings. Why does a solvent free epoxy coating contain VOC , and what is the difference between a solvent free epoxy, and a 100% solids epoxy coating? PF

Answer:

A 100% solids epoxy coating contains no solvents, no VOC and retains the same level of thickness from the time they are applied to the time they dry. There is currently no clear universal definition of a Solvent Free Epoxy Coating. The generic name indicates that the epoxy coating should be “solvent free”, but when looking at these coatings in the market today, we see that that is not always the case. To be able to spray apply such a solvent free coating through single feed airless spray equipment, the viscosity needs to be low enough to get a good spray pattern without the need for thinning with solvents. A very common formulation approach for solvent free epoxies is to use low viscosity liquid Bisphenol A or Bisphenol A/F epoxies that have been modified with reactive diluents. The epoxy binder is cured with low viscosity polyamine or polyamide curing agents that can be supplied with 30% benzyl alcohol as a solvent to further lower viscosity, and which is compatible with the epoxy, and aids the cure. In many cases the viscosity needs further reduction to reach optimal application properties, so 10 weight % or more benzyl alcohol solvent can be added as a non-reactive epoxy resin diluent.

Without any scientific proof (that we are aware of) benzyl alcohol has been claimed to remain as a solid in epoxy coatings, but benzyl alcohol is an aromatic alcohol with a boiling point temperature of 205 C and should strictly speaking (in our opinion) be classed as a solvent, and contribute to the coating’s VOC [1] content. Some argue that due to benzyl alcohol’s high boiling point temperature most of it will not evaporate or diffuse out of the coating film. There is however a reason why over the last two decades we have seen solvent free epoxy coatings for potable water tanks move towards benzyl alcohol free formulations as it has been observed that over time the solvent diffuses out of the coating film giving taste and smell to the potable water [2,3]. The significantly lower practically determined volume solids, compared to the values calculated treating benzyl alcohol as a non-volatile, is a strong indication that it is in fact volatile and should be classified as a solvent.

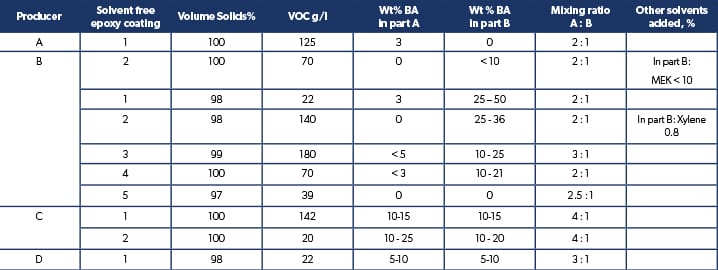

The benzyl alcohol contents in the epoxy base and curing agent part of marine solvent free epoxy tank coatings taken from the coating manufacturers material safety data sheets, are shown in table 1.

Table 1. Benzyl alcohol (BA) content in some typical marine solvent free epoxy cargo and potable water tank coatings.

From the table it is clear that not all paint manufacturers count benzyl alcohol as a solvent that increases VOC and lowers volume solids of the coating, so we get the unfortunate situation that solvent-free coatings that should have very close to 100% volume solids and VOC 0 g/l can vary anywhere between 95 – 100% solids, and 0 – 180 g/l in VOC. Considering that ultra-high solids epoxy coatings can have up to 97% VS and down to 50 g/l in VOC, a universal common definition of solvent-free epoxy needs to be made so that users can clearly distinguish between solvent free, ultra-high solids epoxy coatings, and 100% solids epoxy. As the main advantages of solvent free epoxy coatings are very low or no VOC emissions, the possibility to apply thick coating films with little or no film shrinkage and lower film formation stress.

Based on work we did more than a decade ago, we would like to propose the following universal definition for a solvent free epoxy coating to avoid confusion by users. Hopefully, this will start a discussion among relevant stakeholders to agree on a common clear and universal definition.

Michael Aamodt, Alan Guy and Raouf Kattan, Safinah Group

“A ‘solvent free epoxy’ coating can be defined as an epoxy paint where all of the non-reactive components of the formulation have an initial boiling point greater than 250 C at an atmospheric pressure of 101.3kPa. Benzyl Alcohol added to epoxy coatings should be counted as a volatile since it is not reactive and falls within the definition of a solvent according to EU Paint Directive 2004/42/CE. Benzyl alcohol will also lower the practical volume solids compared to that calculated and often stated on data sheets, when assuming it is non-volatile. At the same time its inclusion increases the volatile organic compound (VOC) content of the coating.”

References

1. “Directive 2004/42/CE of the European Parliament and of the Council of 21 April 2004 on the limitation of emissions of volatile organic compounds due to the use of organic solvents in certain paints and varnishes and vehicle refinishing products and amending Directive 1999/13/EC”.

Official Journal L 143, 30/04/2004 P. 0087 – 0096.

2. J. Romero et al. “Characterization of Paint Samples Used in Drinking Water Reservoirs: Identification of Endocrine Disruptor Compounds”. Journal of Chromatographic Science, Vol. 40, April 2002.

3. Aamodt, M., “Eco friendly coatings for potable water tanks offshore”, Offshore Marine Technology, 1st Quarter 2010, 20-21.