This series of articles is intended to highlight industry wide engineering experiences, practical opinions and guidance, to allow improved awareness for the wider public and focused advice to practicing technologists. The series is written by ICorr Fellows who have made significant contributions to the field of corrosion management. The articles in this issue feature contributions from Bijan Kermani and Dmitry Sidorin.

An overview materials optimisation in CCS

A net-zero energy system to hinder or mitigate global warming driven by burning fossil fuel requires a step change in the way energy is being produced and used. This can only be achieved with a broad suite of technologies including improved energy efficiency, introduction of renewable energy and nuclear power. No mitigation option alone will achieve the desired reduction targets, however, they can be made

more influential when complemented by carbon capture and storage

(CCS) process.

CCS with sequestration can contribute both to reducing emissions and to removing CO2 to balance emissions – a critical part of “net” zero goals. CO2 sequestration is a process by which CO2 is removed from the atmosphere and stored indefinitely in underground locations primarily by means of pipelines. In addition to political and environmental incentives, CO2 sequestration is being considered in tertiary recovery for enhanced oil recovery (EOR) to produce residual hydrocarbon. Many oil and gas operators are looking at materials optimisation for such applications.

This Fellow’s Corner combines current status of corrosion threats and materials options for CO2 pipeline transmission and includes a simple roadmap enabling materials optimisation and outlining any technology gaps that may exist. It starts by describing sources of CO2, means of capture, methods of transportation and sequestration.

Sources of CO2, Capture and Sequestration

CO2 emission arises primarily from human activity and mainly from the combustion of fossil fuels used in different industrial sectors. CO2 is also emitted during certain industrial processes like cement manufacture or hydrogen production and during the combustion of biomass.

The first step in sequestration is CO2 capture. This is done through potentially numerous schemes, some commercially available at present, but all with a significant cost penalty. Capture from the atmosphere is done through biological, chemical or physical processes. The capture system may conveniently be divided into three categories (i) post combustion capture (scrubbing), (ii) pre-combustion capture and (iii) oxyfuel capture, details of which are beyond the scope of the Fellow’s Corner.

Having captured CO2, it needs to be transported and stored for long periods. This can be achieved by sequestration, a process by which CO2 removed from the atmosphere is injected and stored indefinitely. There are currently more than 70 CO2 injection projects in the US, injecting more than 35 million tons of CO2 annually, primarily for EOR.

Briefly, sequestration methods includes (i) geological sequestration, (ii) CO2 EOR, (iii) deep ocean sequestration, (iv) mineral and biological sequestration and (v) terrestrial sequestration again, details of which are beyond the scope of the Fellow’s Corner.

While CO2 has been injected into various geologic formations for decades for EOR purposes and acid gas disposal, the idea of permanent CO2 storage, or sequestration, for the purpose of mitigating global climate change is a fairly novel one with few commercial-scale prototypes upon which to draw guidance in the development of a regulatory framework.

Means of Transportation

Once captured and compressed, CO2 must be transported to a long term storage site as schematically shown in Figure 1 (below). In principle, transmission may be accomplished by pipelines, tankers, trains, trucks, compressed gas cylinders, as CO2 hydrate, or as solid dry ice. However, only pipeline and tanker transmission are reasonable economical options for the large quantities of CO2 associated with, for example, a 500MW power station. Trains and trucks could be used in the future for the transport of CO2 from smaller sources over short distances.

Pipelines

CO2 transmission by pipeline and injection into reservoirs began several decades ago. More than 40 million tons per year of CO2 are currently transmitted through high pressure CO2 pipelines, mainly in North America. Most of the CO2 obtained from natural underground sources is used for EOR.

The Weyburn pipeline, which transports CO2 from a coal gasification plant in North Dakota, USA to an EOR project in Saskatchewan, Canada is probably the first demonstration of large-scale integrated CO2 capture, transmission, sequestration and storage.

Ship Tankers

Ships are now used on a small scale for the transport of CO22 . Large scale transport of CO2 from power stations located near appropriate port facilities may occur in the future.

CO2 would be transported as a pressurised cryogenic liquid, for example at approximately 6 bar and -55°C. Ships offer increased flexibility in routes, avoid the need to obtain rights of way, and they may be cheaper, particularly for longer distance transportation. Ships similar to those currently widely used for transportation of liquefied petroleum gas (LPG) and liquefied natural gas (LNG) could be used to transport CO2.

Corrosion Threats and Severity

Dry CO2 is non-corrosive and relatively easily handled using conventional grades of carbon and low alloy steels (CLASs). However, in the presence of water, the situation is more complicated and system corrosivity would depend on water solubility of the CO2/H2O mixture and therefore, materials used in CCS systems can be subject to corrosion threats in which materials optimisation can take a centre stage.

CO2 readily dissolves in water to form carbonic acidic solution that is highly corrosive to many engineering materials. The accelerating effect of CO2 corrosion is a particularly important safety issue when considering the maintenance schedules and operating life expectancies for pipelines that were not originally designed for CO2 transmission use. Choice of materials for handing CO2 is governed by many parameters including physical state of CO2, water content, its purity and level and nature of impurities.

An additional complicating parameter is the presence of H2S and other potential impurities. A limit on the concentration of H2S is important for two complementing reasons including (i) the likelihood of exceeding sour service limits of materials and (ii) as H2S and O2 may lead to the formation of elemental sulphur which makes system corrosivity even more complex. It should be noted that the presence of small amount of water leads to increasing the iron concentration and pH which results to a low corrosion rate. However, this is difficult to predict and quantify.

High levels of CO2 in the CCS process places the operating conditions beyond the limits of existing CO2 corrosion predictive models and in majority of cases application specific testing may be required. Nevertheless, published data by Institute for Energy (Norway) and Ohio University (USA) indicates that in a condition where CO2 is more than around 50 bar, corrosion rate of CLASs can be estimated to be around 1/10 that predicted by conventional corrosion prediction models.

Materials Optimisation Guidelines

The first step in a systematic materials optimisation process, is to explore the feasibility of using CLAS as it offers satisfactory mechanical properties and economy, although has poor corrosion resistance. System corrosivity assessment therefore is necessary to establish the likelihood of success in using CLASs an area in need of fine tuning. Here a broad guideline is given for handling CO2.

CO2 Only

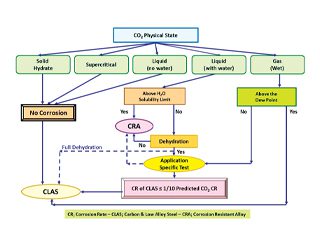

CO2 can exist in variety of physical states depending on the temperature and pressure. The physical state of CO2 and respective approach to materials selection for CO2 transmission in form of a guideline is shown in Figure 2. The guideline is divided into five conditions depending on the physical state of CO2.

The guidelines in Figure 2, excludes the effect of contaminants (H2S, O2, SOx) and applicability limit for H2O as there are no systematic data on these parameters.

It is apparent that successful utilisation of CLAS is highly dependent on the absence of water and other impurities in which thermodynamic analysis to confirm absence of water throughout the pipeline or tubing over the operational life is essential.

CO2 and Oxidizing Agents

CO2 transmission in the presence of oxidizing gases such as SO2, SO3 and O2 becomes even more complicated. Again in the absence of water, there is no likelihood of corrosion. However, in the presence of water, a combination of oxidizing species (SO2, SO3 and O2) and acidic gases (CO2 and H2S), likelihood of corrosion becomes a serious issue. In such situations, a more prudent approach should be adopted and thermodynamic analysis to ensure lack of water throughout the system and design life becomes even more essential. In practice, injection of CO2 with oxidizing agents should not be contemplated unless proven otherwise. The option is to either remove the oxidizing agents, implement total dehydration or the use of an appropriate grade of corrosion resistant alloy (CRA).

References

1. B Kermani and D Harrop, Corrosion and Materials in Hydrocarbon Production; A Compendium of Operational and Engineering Aspects, Wiley, 2019.

2. Carbon Capture, Transportation, and Storage (CCTS), Aspects of Corrosion and Materials, ed B Kermani, NACE International, 2013.

Figure 2 – Materials option guideline for CO2 sequestration.