The cart is empty!

TÜV Rheinland Successfully Conducts ICorr PCI Training in Shanghai, Empowering Professionals in Coating and Corrosion Protection

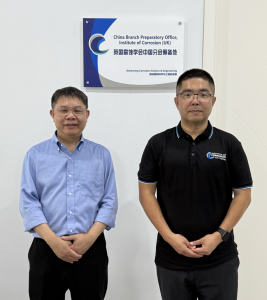

On 4th June 2025, TÜV Rheinland, Shanghai, successfully hosted multiple sessions of ICorr PCI (Protective Coating Inspector) Level 2 and Level 3 training courses, providing Chinese professionals with advanced knowledge in coating and corrosion protection.

These internationally recognised certification programs equipped participants with critical skills to excel in industries such as oil & gas, marine and infrastructure.

The intensive training covered key topics including coating inspection standards, failure analysis, and quality control, enabling attendees to enhance their technical expertise and career prospects.

Two participants, who were voted as outstanding candidates in 2025 H1, shared their experiences.

•“The trainer combined theory with real-world case studies, making complex concepts easy to understand. Earning this Level 3 certification has significantly boosted my credibility in the industry. Beyond the course content, TÜV Rheinland’s training organisation was impeccable—from venue facility to accommodation arrangement. Their team provided seamless support throughout the program” — Qianwei Zhu, Technical Service Supervisor, Jotun, China.

•“L2 course gave me a solid foundation. The hands-on practice and detailed feedback from instructors were invaluable. I now feel confident to take on more responsibilities at work.” — Lu Taijin, Quality Assurance Department Manager, Guangxi Jingdian Steel

Structure Co., Ltd.

Contact

TÜV Rheinland, Shanghai offers a wide range of ICorr approved training courses and maybe contacted at:

Tel.: +86 10 8524 2141

Fax : +86 10 8524 2200

Mobile : +86 139 1179 0253

Email: Jing.Fang@tuv.com

TÜV Rheinland (China) Ltd, Room 301, 3F and Room 403, 4F, Building 4, No. 15, Ronghua South Road, Beijing

Economic-Technological Development Area, Beijing, China.

www.tuv.com

Photo: (From Left to Right): Tiger Hu (Tutor), Lu Taijing, Zhu Qianwei, David Wang (TUV Rheinland Industrial Inspection VGM).